The word cardboard is used to refer to any material used in the packaging industry.

However, there are two types of material used in the packaging industry, one is the cardboard and the other is the corrugated board. Although they look similar the corrugated boxes are more durable than carton boxes. They are characteristically different and have their advantages and disadvantages. By knowing the difference, you will be well placed to order the right material for your product to be safely transported.

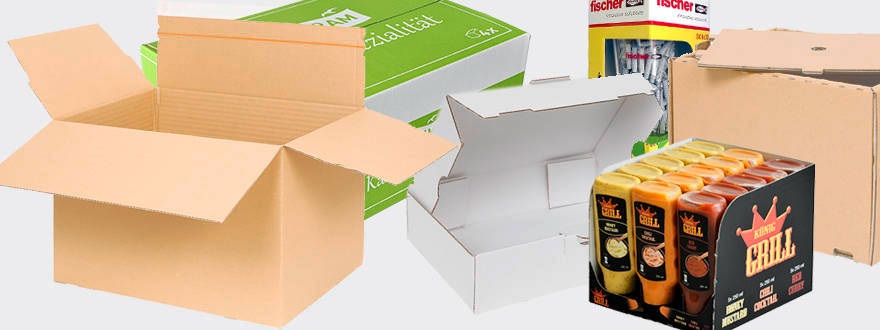

Cardboard

Basically refers to thick paper or heavy paper pulp-This is the kind of paper used for greeting cards or cereal boxes.. They are also used in packaging of light goods for transportation. They are used for small items of daily use like cereals, cookies and chocolates.

Corrugated Boxes

Corrugated is made up of three layers of paper that is the inner liner, the outer liner and the middle wavy paper binding the two. The middle wavy paper is the corrugated paper from which the board derives its name. The corrugated box was considered magical when it was invented and immediately patented.

Here are the special properties of the corrugated box that makes it so popular::

- The corrugated box is made of three sheets of Kraft paper and glue and hence is inexpensive.

- More than half of it is air, and hence is light.

- It is eco friendly being biodegradable and it can be recycled.

- It is rigid compared to even a thicker sheet of paper.

- It is strong and resistant to puncture.

- Even when crushed, it does not crumble like a wood box.

- Corrugated can be folded for ease of shipping.

The disadvantage of the corrugated box are few compared to the advantages. They can easily be cut and they are not water friendly. When in contact with water, they turn soggy. The latter is not a big disadvantage as the boxes are normally kept in dry warehouses.

The strength of the corrugated boxes is determined by the type of the inner and outer layer, the middle corrugated sheet and the distance between the two layers; number of corrugations and the material type. The engineers design the type of corrugated material needed as per the requirement of the packaging that includes the weight, distance and the frequency. To ensure that your product is transported safely, it is essential to engage the services of an experienced packaging company; emballage personnalise Netpack is one such reputable company.